Do you rely on metal manufacturers for your metal parts? Are you looking for fewer flaws and more effective equipment? Precision manufacturing of metal pieces and parts isn’t easy. Stainless steel and aluminum are incredibly valuable and useful materials, but their rigidity and strength make them hard to work with. This is where professional metal forming enters the picture!

With experienced professional metalworkers at your service, your metal parts and pieces can be created faster and more efficiently while being far more effective than mass-produced metal pieces. You can enjoy high-quality metal parts made to your exact specifications – never again will you have to make do with off-the-shelf pieces! Call Brandywine Valley Fabricators and discuss what we can do for you!

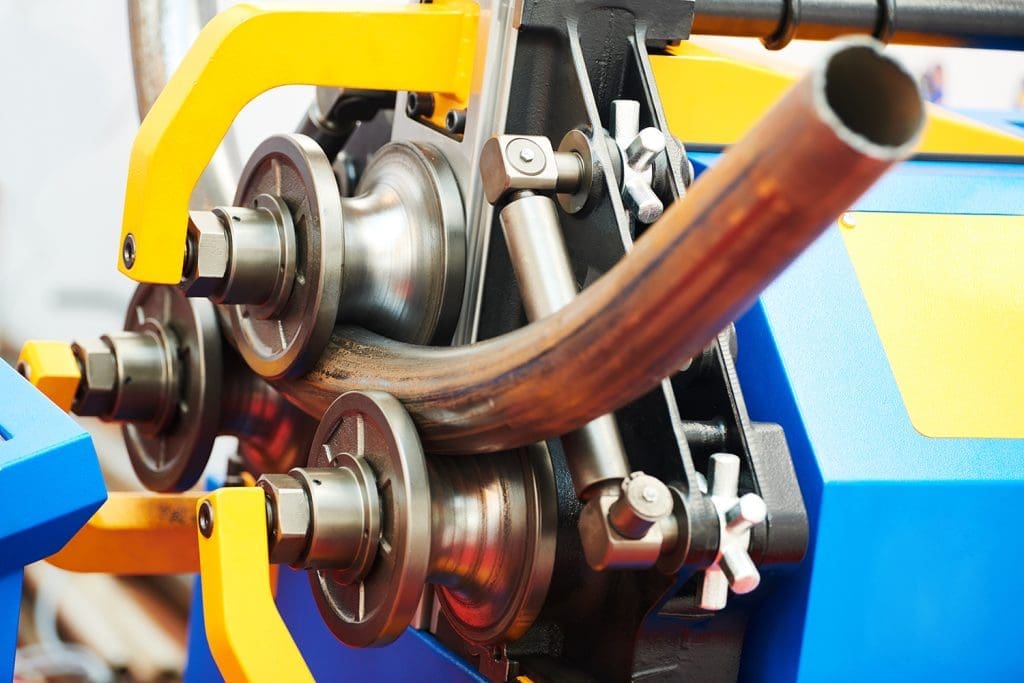

Bending for Curved Lines

Bending is the most common method of metal forming and shaping, which involves simply deforming a piece of metal along a straight axis. This technique fabricates almost all kinds of metal parts, with proper application resulting in precise shapes and angles.

- Car Frames and Panels

- Ship and Boat Hulls

- Construction Piping

- Industrial Equipment Frames

Bending pipes and sheet metal is a fast and efficient route toward a custom piece and is far cheaper than custom foundry work – however, bending can pose the risk of deformation or cracks and faults. Metal forming and bending machinery operators must showcase their precision and care to maintain integrity.

Punching for Precision Removal

Punching metal sheets and pieces creates parts with fine details and intricacies. Punching involves striking metal with a steel punch, removing material, and creating unique and specific shapes. This process requires a sturdy material to stand up against these forces without causing deformation across the piece. This is most common in stainless steel and aluminum parts used for:

- Vehicle Body Panels

- Fuselages and Aeronautics Pieces

- Medical Equipment

This process is great for any pieces that demand intricate shapes but might not be suitable for the armatures of a CNC metal machining tool. This is most appropriate for materials like stainless steel, which can withstand more sharp manipulation and extreme pressures of metal shearing equipment.

Rolling for Consistent Thickness

Metal rolling machines use two large, solid cylinders that squeeze and rotate the workpiece together, compressing and shaping the metal sheet. Rolling creates thinner, standardized sheets of metal that shine even brighter. This quality is invaluable for:

- Structural Steel

- Fabricated Plates and Strips

- Metal Pipes, Rods, and Cylinders

- Sheet Metal Production

Custom metal rolling can have high production rates and highly consistent quality. However, this process is limited in how complex a shape can be produced. For the right project, this process is one of the fastest and most efficient metal-forming techniques we use!

Cutting for Crisp Lines

Metal shearing tools will cut metal sheets into specific shapes and sizes using extremely sharp and powerful shearing tools. These tools create clean cuts that can be made quickly and consistently. This can be done at room temperature and produces very little waste.

- Construction Brackets, Beams, and Columns

- Aerospace Wings and Fuselage Sections

- Household Appliance Bodies

Shearing has many benefits as a process, from high-volume production to flexibility and agility for creating variable cuts. However, there are material limitations, as harder materials may damage the blades of the shearing machines, and complex shapes are not suitable for this metal-forming method.

Forging for Controlled Shapes

Forging is a classic metal forming technique that can augment the strength of your parts by creating more compressed and well-shaped pieces than other metal fabrication techniques. The forces involved can create very strong parts and sharp edges:

- Cutting Tools

- Engine Parts

- High-load Transmission Components

Forging is a much more involved process, meaning it can create complex parts that other techniques simply cannot. However, this also means that certain restrictions and costs limit the value of this process for very large or small jobs.

Trust in Brandywine Valley Fab’s High-Quality Results!

Don’t hesitate to reach out when you need stainless steel or aluminum parts crafted to perfection! Custom metal forming isn’t just a fine craft for high-end businesses – it’s an essential service for companies relying on metal parts and pieces for day-to-day business.

When you work with us, you get a business partner who wants the same results that you do. With our commitment to customer service and quality craftsmanship, you will return to us for every project you have for years to come! Call us today and get started!